WHISKY CRAFTING

The art of whisky-making

When we first set out to build a distillery, we knew we wanted to use the best possible kit, traditional methods and the highest quality raw ingredients. Thankfully, we had the guidance of renowned industry legends Harry Cockburn, former Distillery Manager at Bowmore, and Dr Jim Swan, fondly known as ‘the Einstein of whisky’ for his formidable knowledge of the science of distillation and maturation.

-

01

HARVEST TIME

We begin at the farm. Right from the start, we are committed to using 100% locally grown barley – all the barley that we use to craft our single malt whiskies has been grown here in the Cotswolds.

-

02

TRADITIONAL MALTING

Once the barley has been harvested, it heads to Warminster Maltings, Britain’s oldest working maltings. Using the same techniques they’ve used for hundreds of years, the maltmen steep the barley before turning it on the malting floors by hand for several days. The final step is to kiln dry the malt and then send it up to us at the distillery.

-

03

MILLING AND MASHING

Each morning, our distillers begin by grinding up the malt in our mill so that we can extract the fuel inside it more easily. The ground-up malt, known as grist, falls directly into our 0.5 tonne mash tun where we mix it with hot water in three stages. The heat of the water triggers reactions in the malt that release its sugars into the water, turning it into a liquid known as worts.

-

04

FERMENTATION

We run the worts off into one of our steel washbacks, collecting 2,500 litres from one mash. We then add two strains of dried yeast, Anchor and Fermentis, which were selected not only for their consistent yields but also for the excellent flavours that they produce. The yeast turns the sugars in the worts into alcohol and we allow this process to continue for over 90 hours in order to allow the wash to fill with bacteria which produces acid and combines with the alcohol to form fruity compounds called esters.

This was one of Dr Jim Swan’s masterstrokes – making sure that the wash was loaded with esters that would give our spirit a fantastic fruity complexity.

-

05

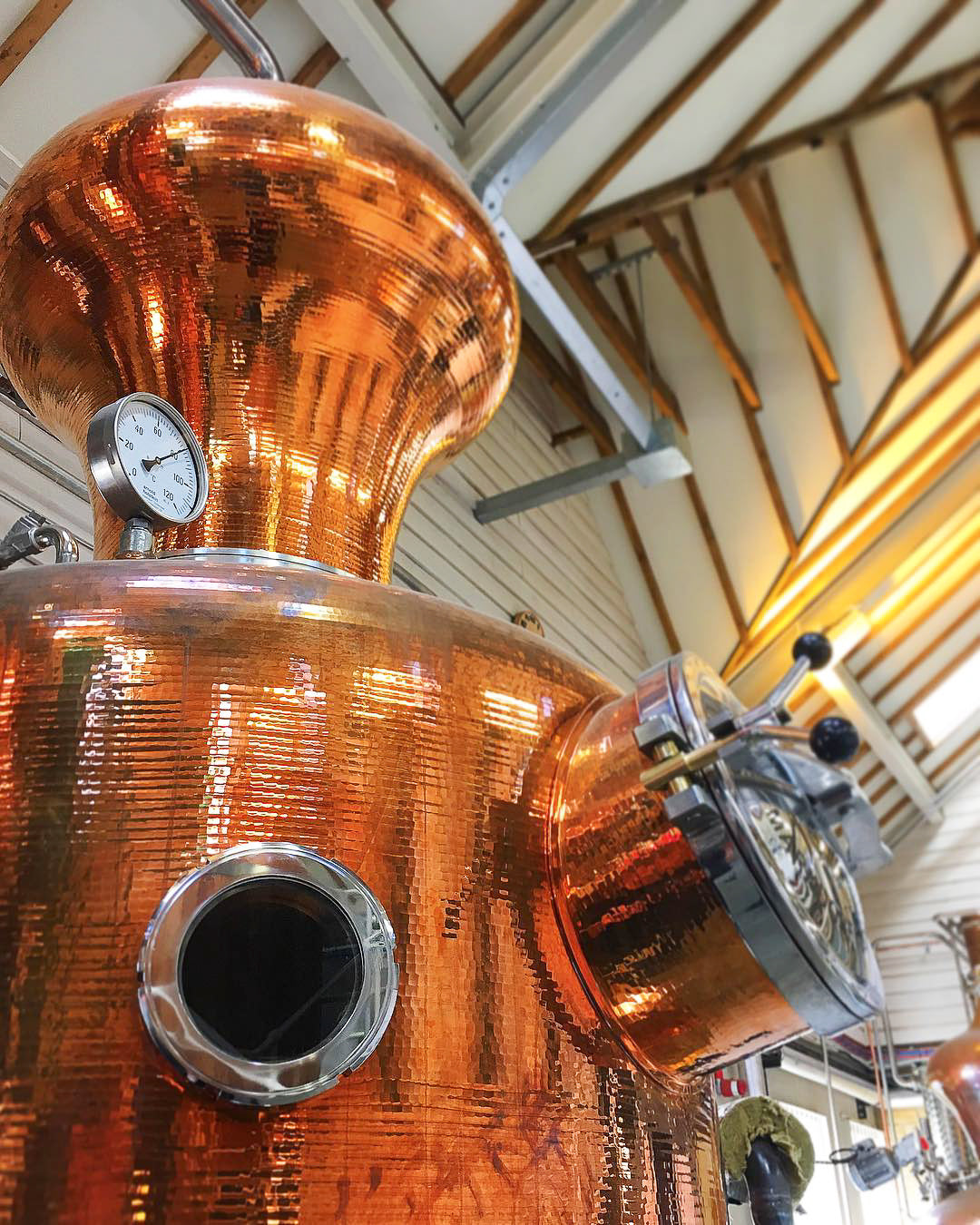

DISTILLATION BEGINS

On day five, we begin our double distillation process. We start by boiling the fermented wash in our wash still to collect the Low Wines - a liquid containing all the alcohol and flavour compounds from the wash.

We then distil the Low Wines in our spirit still. Our cut points (the moment we switch from foreshots > hearts > feints) are also quite unusual. The fruity esters created during fermentation appear early on in the distillation, so in order to capture them in our spirit we switch from foreshots to hearts after only a few minutes. The cut to feints also happens sooner than it usually would, meaning that none of the heavier, rougher compounds will make it into our spirit.

-

06

READY TO BE CASKED

The heart cut, a colourless and fruity spirit, is known as new make spirit, and it comes off the still at 75% ABV. Thanks to our unusual fermentation process and cut points, it is already smooth enough to drink and full of fruity flavours.

We reduce this to 63.5% ABV by adding demineralised water and then it is ready to be casked. We fill the spirit into a combination of oak casks and then place it in our warehouse, where it will be left to mature until it is ready to be bottled.

Gin CRAFTING

Discover how we craft our award-winning Cotswolds Dry Gin - a delectable blend of nine carefully considered botanicals.